The dairy industry has evolved dramatically over recent decades, with technology playing an increasingly vital role in farm productivity and animal welfare. Today’s successful dairy operations require more than just good land and healthy cattle—they need modern equipment that streamlines operations, improves milk quality, and supports sustainable farming practices. Whether you’re upgrading an existing operation or starting fresh, understanding essential modern equipment can make the difference between struggling and thriving.

Automated Milking Systems

Gone are the days when manual milking was the only option for dairy farmers. Modern automated milking systems have revolutionized how farms operate, allowing for consistent milking schedules that align with natural cow behavior rather than human convenience. These systems monitor milk production in real-time, track individual cow health metrics, and maintain optimal hygiene standards throughout the milking process.

The benefits extend beyond labor savings. Automated systems reduce stress on animals by allowing them to be milked when they’re ready, which can actually increase milk production. The data collected helps farmers identify health issues early, track productivity trends, and make informed decisions about herd management.

Cooling and Storage Solutions

Maintaining milk quality from the moment it leaves the cow until it reaches the processor is critical for any dairy operation. Modern bulk tank cooling systems rapidly chill milk to safe temperatures, preventing bacterial growth and preserving freshness. Advanced refrigeration units maintain precise temperature control and often include monitoring systems that alert farmers to any temperature fluctuations that could compromise the product.

Proper storage capacity is equally important, allowing farms to accumulate milk between pickups without quality degradation. Investing in reliable cooling equipment protects your product, your reputation, and your bottom line.

Precision Feed Management Equipment

Nutrition directly impacts milk production, cow health, and farm profitability. Modern feed management systems have transformed how dairy farms approach nutrition, moving from guesswork to precision. Automated feeding systems deliver customized rations to individual animals or groups based on their specific nutritional needs, lactation stage, and production levels.

These systems reduce feed waste, ensure consistent nutrition, and free up valuable labor hours. Some advanced setups include weighing systems that track feed consumption patterns, helping farmers optimize rations and identify animals that may be experiencing health issues based on changes in eating behavior.

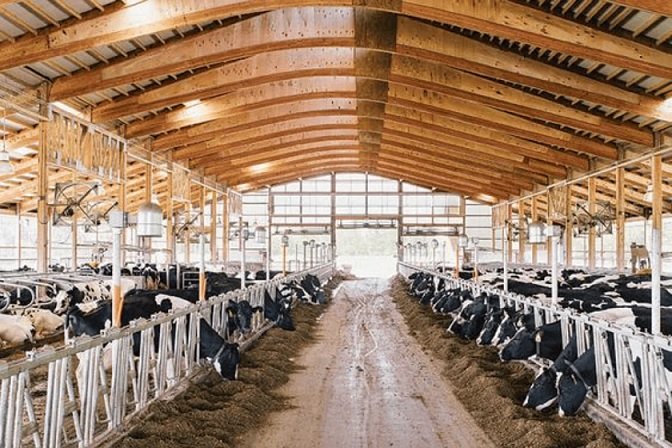

Ventilation and Climate Control

Creating an optimal environment for dairy cattle significantly impacts their health, comfort, and productivity. Manufacturers such as Tristar provide ventilation systems and advanced climate control equipment that ensure optimal barn and milking parlor conditions year-round. Proper airflow reduces heat stress during summer months, minimizes respiratory issues, and helps control moisture levels that can lead to bacterial growth.

Modern climate control goes beyond simple fans and heaters. Sophisticated systems monitor temperature, humidity, and air quality, automatically adjusting to maintain optimal conditions. This investment pays dividends through improved animal health, reduced veterinary costs, and increased milk production from comfortable, stress-free cattle.

Manure Management Systems

Effective waste management is both an environmental responsibility and a practical necessity for dairy operations. Modern manure handling equipment makes this challenging task more manageable while turning waste into a valuable resource. Automated scraper systems keep barns clean with minimal labor input, while manure separators can process waste into usable bedding material and nutrient-rich fertilizer.

Advanced composting systems and anaerobic digesters can even generate renewable energy from manure, offsetting farm energy costs while reducing environmental impact. As regulations around agricultural waste become more stringent, having proper manure management equipment isn’t just good practice—it’s essential for long-term viability.

Herd Health Monitoring Technology

Prevention is always more cost-effective than treatment in dairy farming. Modern monitoring systems use sensors and tracking devices to continuously assess individual animal health, detecting subtle changes that might indicate illness before symptoms become obvious. These systems can monitor rumination patterns, activity levels, body temperature, and other vital indicators.

Early detection allows for prompt intervention, reducing the severity of illness, minimizing treatment costs, and preventing disease spread through the herd. The data collected also helps farmers identify patterns and make management decisions that improve overall herd health.

Conclusion

Success in modern dairy farming requires strategic investment in equipment that enhances efficiency, animal welfare, and product quality. While the initial costs may seem daunting, the right equipment pays for itself through increased productivity, reduced labor costs, improved milk quality, and healthier animals. As the industry continues evolving, farms that embrace modern technology position themselves for sustainable long-term success in an increasingly competitive market.